Semi-auto Bottle Blowing Machine

Volume range: 10ml -- 2000ml

Application: PET PP PC bottles

Capacity (production): 800-1200pcs/hr

Volume range: 10ml -- 2000ml

Application: PET PP PC bottles

Capacity (production): 800-1200pcs/hr

1. Machine description

Semi-auto series stretch bottle blowing machine is suitable for producing different shapes of bottles from PET/PP/PC preforms.

A.1. Advanced PLC control system with a use-friendly panel and time-control precision of PLC up to 0.01second;

A.2. Equipped with special designed air storage unit in machine to reduce the pressure of air compressor, and also supply abundant air to blow bottles;

A.3. Far-Infrared preform heater (oven) to heat even thick preforms fully;

A.4. Heating lamps are adjustable in directions to suit various performs;

A.5. Independent temperature control system for different heating lamps to get ideal preform heating results;

A.6. Operated only by one person without special training;

A.7. Easy and simple installation & maintenance;

| ITEMS | UNIT | YC-2LA/B |

| Max.Volume of Products | L | 2L (2-cavity.),

3L (1-cavity.) |

| Theoretical Output | PCS/HR | 800BPH: 1 blower 1200BPH:2 blower |

| Neck Diameter | MM | 10-80 |

| Max.Container Diameter | MM | 100 |

| Max.Container Height | MM | 200 |

| Max.Mold Thickness | MM | 210 |

| Mold Opening Stroke | MM | 160 |

| Working Pressure | Mpa | 0.8-1.0 |

| Blowing Pressure | Mpa | 2.0-3.0 |

| Heater Power | KW | 14 |

| average energy consumption | KW | 7-8 |

| Power of Main Blower | KW | 0.2 |

| Measurement of Main Machine | M | 1.6×0.6×1.6 |

| Weight of Main machine | KG | 500 |

| Measurement of Oven | M | 1.3×0.6×1.1 |

| Weight of Oven | KG | 250 |

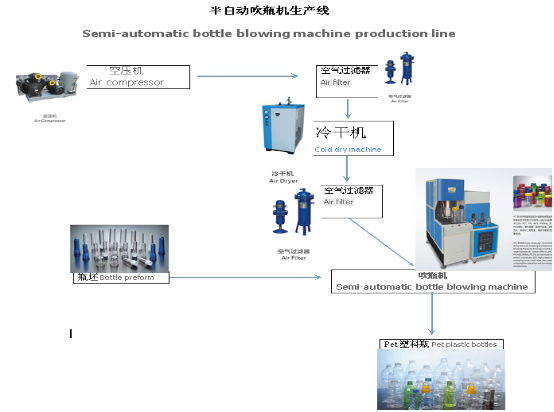

Work Flow:

2. Auxiliary equipment series

2.1 Air compressor

Sunrise is famous brand from Taiwan.

Air compressor is responsible for supplying high pressure air to bottles to make sure the brightness and perfect edges.

| Model | Air delivery | Discharge pressure | Motor power | Speed | External Dimensions | Weight | |

| M3/min | MPa | KW | HP | r.p.m | MM | KG | |

| 1.2/30G | 1.2+vertical tank | 3.0 | 11 | 15 | 620 | 1900X1000X1300 | 600 |

2.2 Water Chiller

Water chiller’s functions:

1st, to make bottle mold cold in order to protect mold and bottles.

2nd, to fast chill bottle shape.

| Model | Chilling capacity | power | Chilled water pump power | Max. flow rate of chilled water | Tank capacity | Extermal Dimensions | Weight | |

| KCal/Hr | KW | HP | KW | L/min | L | MM | KG | |

| WC03 | 7,740 | 2.25 | 3 | 0.37 | 90 | 45 | 850x520x900 | 100 |

2.3 Air Dryer Group

| technical data | 10NF | |

| Nm3/min | 1.6 | |

| voltage | 220v | |

| (KW)Compressor power | 0.59 | |

| Fan power | 60 | |

| Pipe diameter | ZG1” | |

| dimension | mmL | 900 |

| mmM | 360 | |

| mmH | 850 | |

| (kg)weight | 100 | |

Air dryer group (air dryer and filters) is devoted to make the high air that from compressor dry and clean. It helps filtrate the impurities and dissolve grease, oil and dirt so that to make sure the air is good enough to blow bottles.

3. Bottle Samples