Description

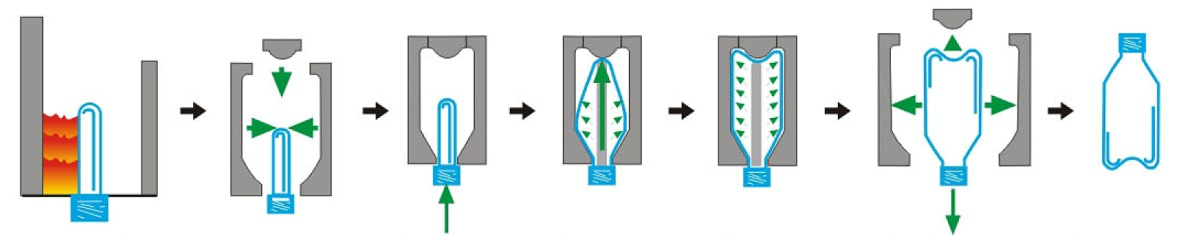

1. Work Flow of Buen Hand Type Bottle Blowing Machine:

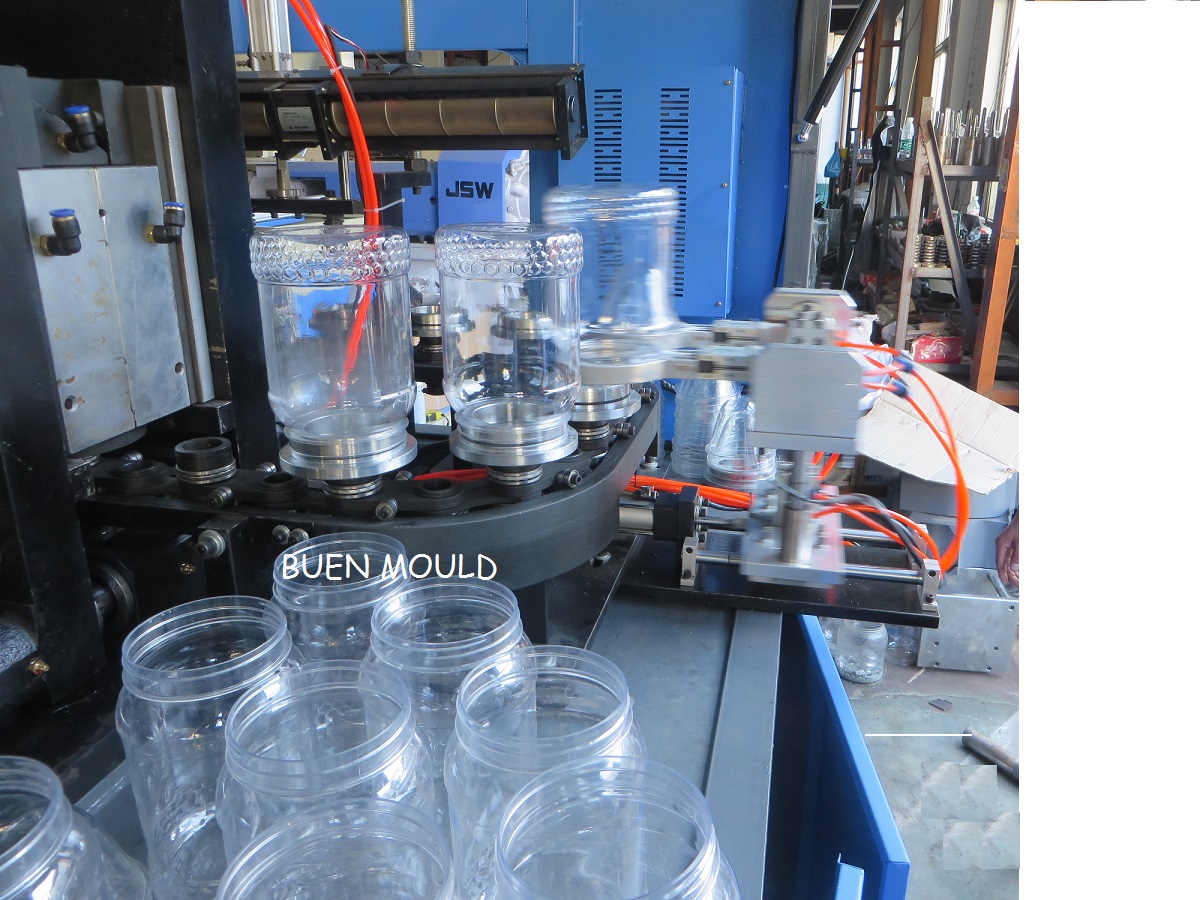

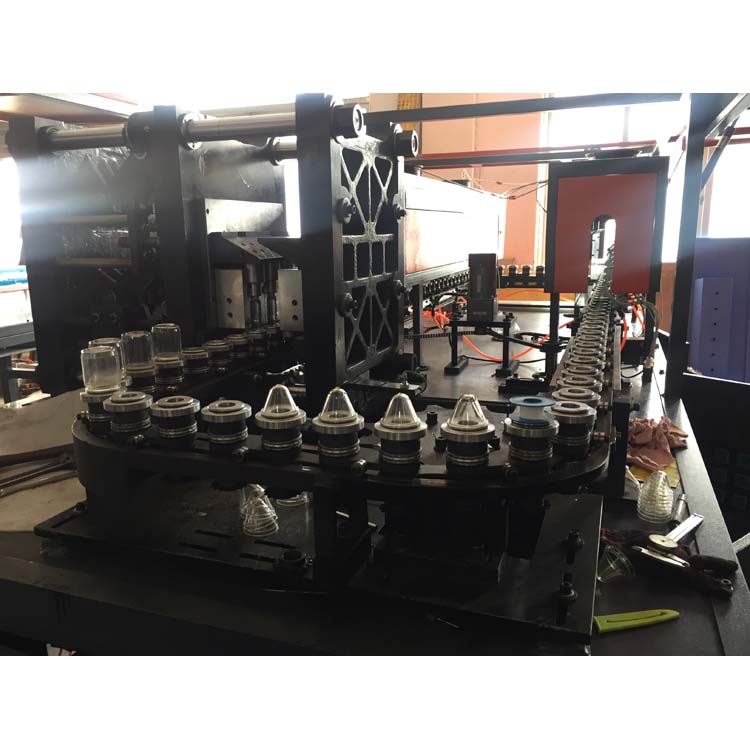

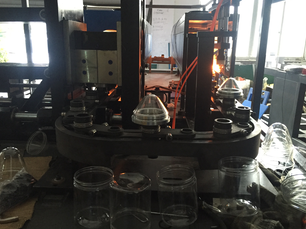

2. Product Show:

3. Machine Parameters

| TYPE | ITEM | UNIT | YC-A2 |

| CONTAINER | Theoretical output | Pcs/Hr | 1000-1200 |

| Max.container volume | L | 2L | |

| Max.neck diameter | MM | 120 | |

| Max.container diameter | MM | 200 | |

| Max.container height | MM | 350 | |

| Number of cavity | Cavity | 2 | |

| ELECTRICAL

SYSTEM |

Actual power consumption | KW | 15-17 |

| Heating power | KW | 25 | |

| Actual total power | KW | 27 | |

| AIR SYSTEM | Operataiting low pressure | Mpa | 0.8 |

| Low pressure consumption

|

M3/min

|

1.2-1.4 | |

| Blowing pressure | Mpa | 2.0-3.0 | |

| High pressure consumption | M3/min

|

1.6-1.8 | |

| CHILLER

WATER |

Operating pressure | Mpa | 0.3-0.5 |

| MACHINE | Machine dimension | M | 3.6×1.7×2.1 |

| Machine weight | Kg | 2500 |

4. Configurations of machine

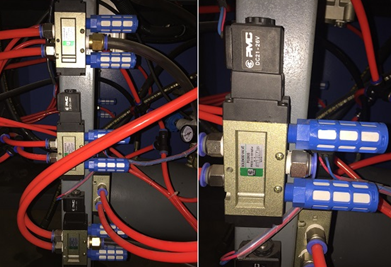

| Photo | Name | Brand | Region |

|

Clamping cylinder

Turn the cylinder Stretching cylinder |

Airtack | Taiwan |

|

Blow air valve | Parker | America |

|

Operating valve | Parker | America |

|

Electrical appliances | CHNT | Zhejiang |

| Manipulator | JingQI | Taiwan |

6.Auxiliary Equipment series

1.High pressure air compressor ad low pressure air compressor.

High pressure air compressor is responsible for supplying high pressure air to bottles to make sure the brightness and perfect edges.

Low pressure air compressor is responsible for supplying low pressure air to bottle blowing machine for operateing

| Model | Air delivery | Discharge pressure | Motor power | Speed | External Dimensions |

Weight | ||

| M3/min | MPa | KW | HP | r.p.m | MM | KG | ||

| 2.4/30 | 2.4 | 3.0 | 30 | 40 | 730 | 2000X1750X1450 | 1250 | |

| 1.6/12 | 1.6 | 1.2 | 11.0 | 15 | 600 | 1750X720X1320 | 410 | |

2.High pressure air coling dryer

Air cooling dryer is devoted to make the high air pressure that from compresor dry and clean ,they help filtrate the impurities and dessolve grease、oil、and dirt so that to make sure the air is good enough to blow bottles.

| technical data | 10NF |  |

| Nm3/min | 2.0 | |

| Inlet pressure | 3.0Mpa | |

| Compressor power (KW) | 0.59 | |

| voltage | 1Ø 220V 50Hz | |

| Fan power (W) | 60 | |

| Pipe diameter | ZG1” | |

| Dimension (L*w*H) mm | 520*360*750 | |

| Weight (kg) | 50 |

3、water chiller

Water chiller’s functions is to make bottle mold cold order to protect mold and bottles , And to fast chill bottle shape.

| Model | Chilling capacity | power | Chilled water pump power | Max. flow rate of chilled water | Tank capacity | External Dimensions | Weight |  |

|

| KCal/Hr | KW | HP | KW | L/min | L | MM | KG | ||

| WC03 | 7,740 | 2.25 | 3 | 0.37 | 90 | 45 | 850x520x900 | 100 | |

4、Air filter(low pressure and high pressure)

| Model | Nm3/min | Height | Diameter | Weight | Outlet |  |

| FS- 30(2.0/12.5)

Low pressure |

2.0 | 620 | 280 | 21

|

Rp1/2’’

|

|

| Kl-2NG(2.0/30-40)

High pressure |

2.6 | 820 | 300 | 20 | Rp1” |

5、High air tank

Air tank is mainly to store abundant air to supply to bottles through air pipes, in other hand it can also protect the compressor from keeping working

| Model | Height | Diameter | Weight | The outlet | Sewage exit | |

| 1.0/30 | 2200 | 800 | 469 | Rp1½” | R3/4” |

6、High pressure tracheal

7. Free spare part lists

| No | Name | Qty | Note |

| 1 | Adjust voltage | 1Pcs |

|

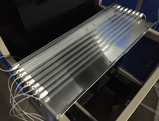

| 2 | The heating tubes | 10 Pcs |  |

| 3 | Sealing ring | 2Pcs |  |

| 4 | Sealing gasket | 6Pcs |  |

| 5 | Proximity switch | 1Pcs |   |

| 6 | PET preform holder | 2pcs |  |

| 7 | The heating module | 2pcs |  |

| 8 | Electricity valve | 1Pcs |  |

| 9 | Silencing valve | 2Pcs |  |

| 10 | Start Switch | 2Pcs |  |