Description

Product description

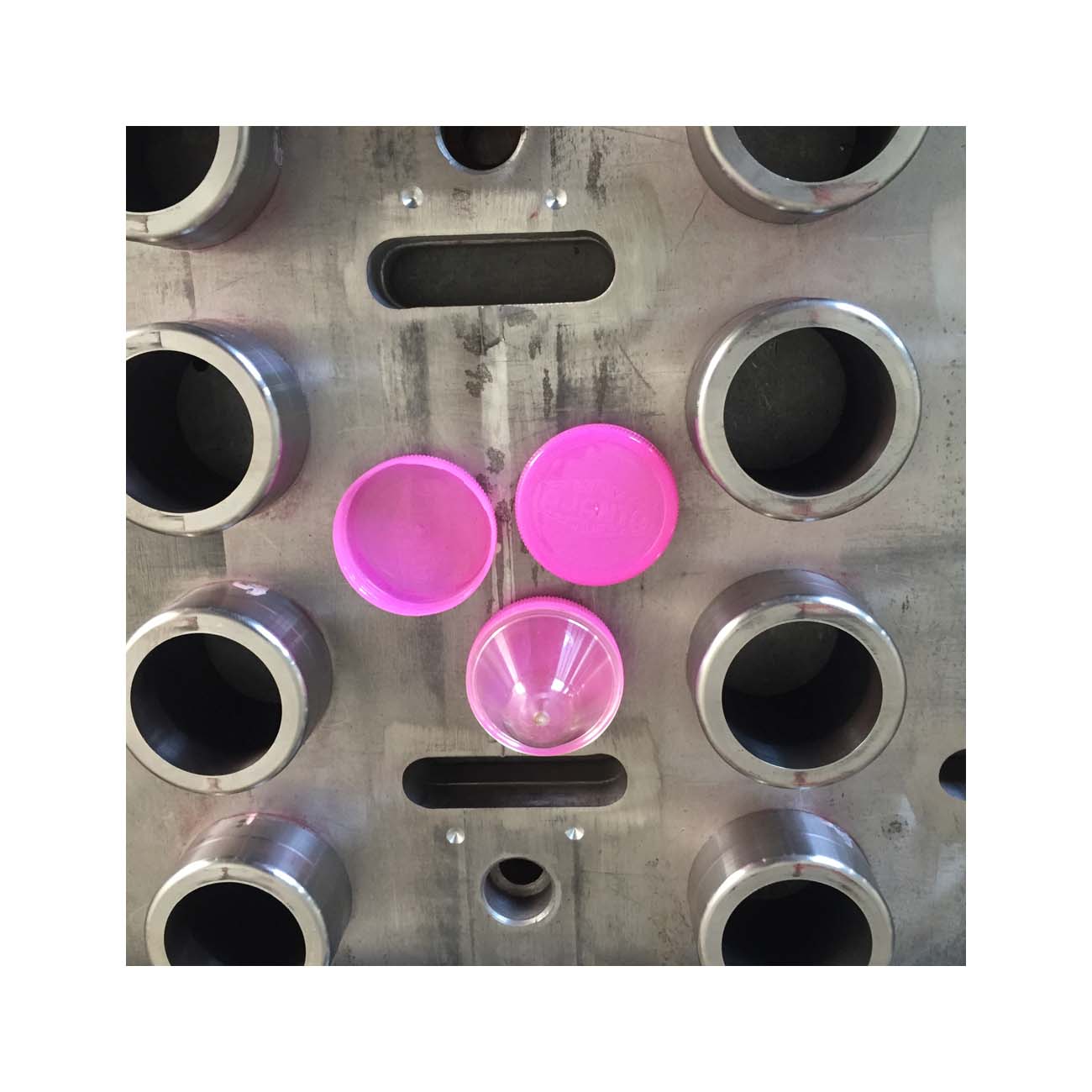

we can supply: mineral water cap mould, beverage cap mould, 5gallon cap mould, theft proof cap mould, shampoo cap mould, different kinds of oil cap mould, sport cap mould, cosmetics cap

mould, wine cap mould.

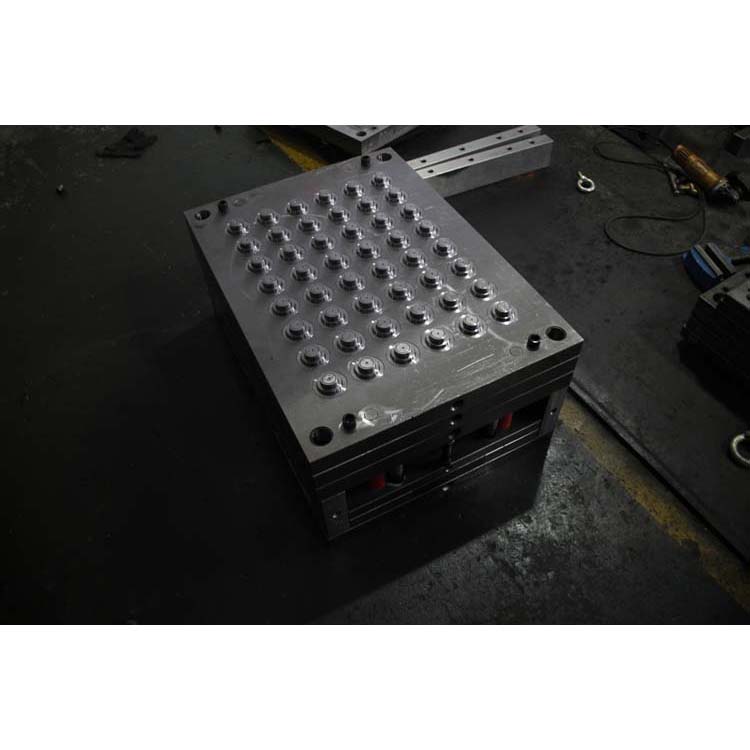

1.MOULD FEATURES

1), Core,Cavity and Neck can be interchanged.

2), Excellent hot runner system and cooling system.

3), High quality materials and proven mold design ensure long life time.

2,HOT RUNNER SYSTEM

1), Less energy cost and pressure lost

2), Use imported heaters,like Germany HOTSET and Italy ROTFIL

3), Cavity-to-cavity control system ensure nozzle temperature fluctuates within 1oC

4), Hot Runner Balance design ensures evenly force,uniform heating and identical preforms.

3,COOLING SYSTEM

1), Spiral Water Cooling Way on cavity enhances cooling performance.

2), Cooling System on neck and move neck plates enhance cooling performance.

3), Precise Dis tributary Plate distributes cooling water into cavity evenly,quicken preform cooling.

Our services

Our services

. Seller will send buyer tooling process report each week.

. Seller shall provide buyer all the technical documents relating to the product.

. Seller shall send buyer free sample of edible oil preforms for 2 times for product checking.

. Seller shall provide buyer the mould test video to see mould runningt status.

. Seller shall support buyer in sample and mould checking and give positive reply in technical problems.

. Guarantee time: 2 year.

. Payment terms: 40% prepayment, balance shall be paid before shipment.

. Delivery: 50 days upon design confirmation.

After guarantee time, in case any NON-HUMAN damage, seller shall bear the cost for cost.

. Seller shall provide buyer with relative technical assistance of 500ml 1L 5L 4 cavity edible oil bottle preform mold

Packaging &Shipping

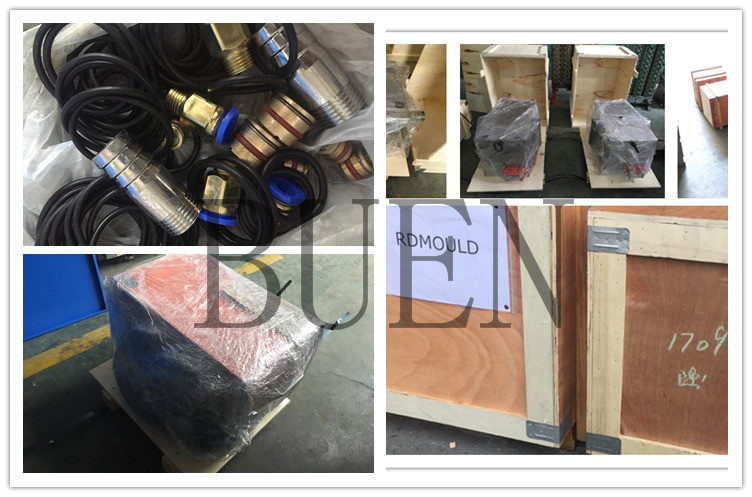

Outside: Standard waterproof wooden box; Inside: film paper + packing belt reinforced

To make sure the product packaging integrity and safety;

Shipping methods:

1. By sea; 2. By air

(recommend big product such as blowing machine and preform molds)

3. By express: TNT, EMS, DHL, Fed Ex, UPS etc.(suitable for free samples)

FAQ

FAQ

1.Q:Are you a factory or trading company?

A:We are factory

2.Q:Where is your factory located?

A:Our factory located in Huangyan-Town of Mold in china,Near Shanghai and Ningbo port,3 hours by train from Shanghai,2 hours by air from Guangzhou

3.Q:How can I get some samples?

A: We are honored to offer you free samples.But you will pay express charge.after place an order will refund double charge.

4.Q:What is your main product?

A:Our factory focus on preform mould,cap mould,pharmacist mold and blow mold,simultaneously we working with the domestic famous injection machine and blow machine,help you to solve all sorts of problem.

5.Q: what is your terms of payment ?

A: 50% advance payment against contract, the balance should be paid before shipment

6.Q:How about quality control in your factory?

A:Quality is our culture.we pay great attention to quality control from beginning to the end.Every piece of goods is tested strictly before packing and delivery

7.Q:How about guarantee for machine and molds?

A:For machine offer one year guarantee.For molds we offer one year or 3 million shot guarantee.based on which comes first

8.Q:ls there complete machine include mold and other accessories?

A:Yes,what we are provide is the complete system and you will no need spend a lot to find thesuitable accessories machines

9.Q:What is the language of PLC and touch panel?

A:Don’t worry ,we will translate the language in English,make sure you will have a easy operation

10.Can you help us with the shipment of this machine and molds?

A:Yes,With honor we have our special shipment company which already cooperate for longtime,you can contact us for the freight,we will give you the best price we can.also you can ask you own shipping forwarder,we help you done other things,customer satisfy is our target

Order process for Mold

Stage 1

- Make product design drawing as per original sample or customer’s concept

- Get machine specs from buyer

- Plan mould specification

Stage 2

- Make mould drawings according to the buyer’s requirments & machine specs.

- Approval of mould drawings by the buyer’s

Stage 3

- Order steel & standard parts and start machining work on core,cavity & mould base

- Fitting,adjusting,polishing

- Detailing & Assembly

Stage 4

- First trial -To check mould injection dimensions, fittings and mark corrections

- Second trial-Detailed inspection,corrections

Stage 5

- Send mould testing video & photos to the buyer

- Send trial samples by courier to customer and take approval

- After do final corrections,do final trial-inspection

Stage6

- Pack moldswith wooden case

- Delivery mould by sea or air